Magnetic components have utility in various applications and devices. They use an internal magnetic field that can alter electrical currents. Due to their many uses, businesses across diverse industries use these components for their products.

However, there are also different types of components. We’ll break down the different types of magnetic components, discuss what applications they’re used for, and the industries that can benefit the most from their applications.

What Industries Use Magnetic Components?

Due to their versatility, many businesses and organizations can benefit from these revolutionary components. Industries that use these components the most often include:

- Electronics: Many magnetic components are in electronics like computers and mobile devices. When manufacturers choose the right components, they can dramatically increase power efficiency while also reducing size.

- Appliances: Whether in a fridge or washer at home or advanced industrial appliances for oil rigging, these versatile components play a huge role.

- Automotive: It’s believed that the modern car has more technology than the Apollo 11 rocket that landed on the moon. Key features like climate control, interior and exterior lighting, sophisticated safety programs, dashboard displays, and more require well-regulated voltage.

- Communications: From larger transformers used in advanced telecommunication systems to the cellphone in your pocket, magnetic parts are crucial for successful communication.

- Defense and military: As weaponry, surveillance systems, and transport vehicles become more complex, the more magnetic components become high in demand.

The Two Main Types of Magnetic Components

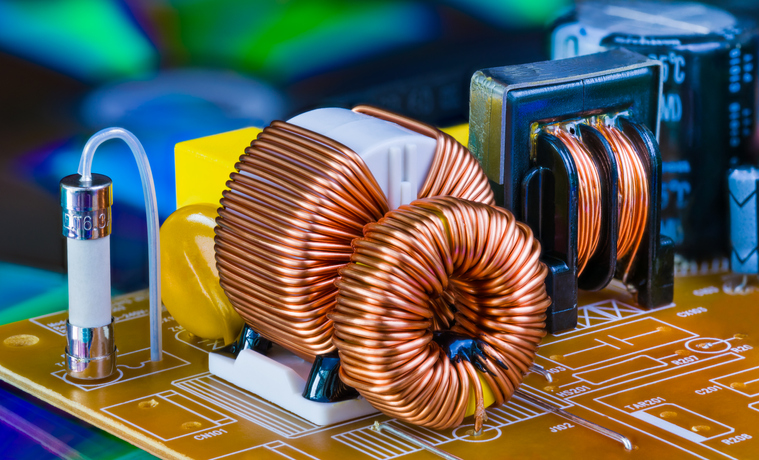

Although there are several types of magnetic components, they can generally be divided into two major groups: inductors and transformers.

Inductors

An inductor is used to slow down the surges in a current by adding resistance. Some applications include:

- Storing and transferring voltage in power converters

- Choking, blocking, attenuating, or filtering electrical circuit noise

- Creating LC circuits or tuned oscillators

Some common inductors industries often use include:

- Common mode choke inductors: These highly efficient inductors are used to eliminate AC line-conducted common-mode noise when switching power supplies/power supply circuits.

- Input inductors: When handled correctly, an input inductor can provide a low AC ripple current for inputs when switching power supplies—a function that’s useful across many industries.

- Low pass filter inductor: For filtering EMI interference while minimizing signal loss, a Low Pass Filter Inductor is an excellent choice and is the most recommended when dealing with a circuit that has different voltages.

- Toroid inductors and choke inductors: These types of inductors are used in many electronics, including medical supplies, manufacturing equipment, test equipment, and power supplies.

Transformers

The main role of a transformer is to either increase or decrease voltage levels while stabilizing a circuit’s voltage level. Transformers consist of three major components: a primary coil, a secondary coil, and a core. Just like inductors, there are different types of transformers:

- Flyback: Flyback transformers are in many devices such as computers, electrical pumps, PoE motors, converters and inverters, and AC-DC power supplies.

- Audio transformers: The purpose of audio transformers is to modify signals between different audio applications for a much better overall sound quality. They do this by matching the impedance and voltage of their respective input and output sources.

- Isolation transformers: Isolation transformers are used to isolate electrical devices from their supply line. Due to this unique capability, medical industries often use isolation transformers because they have smaller power losses, can reduce shock administered to a patient, and are compact.

- Power transformers: These types of transformers are often called electrical power transformers and have a wide range of uses. Uses often include induction heating, inverters, having an unregulated power supply, and traction motion control.

Coils

Coils are often used in conjunction with other custom magnetic parts like transformers. A magnetic coil is made from material typically like copper that winds around a cylindrical or toroidal-shaped core. The purpose of a coil is to transmit heat, electricity, or sound. They are used in major industries, including the following:

- Medical

- Electronics

- Telecommunications

- Aerospace and defense

- Automotive

- Commercial manufacturing

Different types of coils include:

- Universal coil windings are commonly used in transformers where high voltage power is needed.

- Copper foil coil is a reliable material used for many applications across medical, electronic, industrial, and aerospace industries.

- Trapezoidal coil is an innovative coil that follows the same principles as the Helmholtz coil and has recently been used to destroy cancer cells.

Contact Schott Magnetics Today

Magnetic components have a wide range of uses and applications. To make sure you’re using the right component for your business or organization, you’ll want Schott Magnetics on your side. Our team can design, prototype, and manufacture innovative transformers or inductors that fit your needs.

To learn more about the services we offer at Schott Magnetics, call us today.